Product Brief:

Xinxiang Tiancheng Aviation Purification Equipments Co., Ltd(hereafter referred to as Tiancheng) is dedicated to designing and producing high- quality filter elements, filter products and filter machine for coal mining, construction machinery, wind power, thermal power, petroleum, petrochemical, refrigeration compressor and other industries.

Hydraulic Oil Suction filterHydraulic Oil Return filterPressure line pilot filterAir BreatherHydraulic parts

Pilot valve filter elementHydraulic support backwash filter elementEmulsion pump station filter elementDBT High pressure filtration station filter element

Hankison precision filter elementParker precision filter elementGerman ultrafiltration

chilunGearbox filter elementHydraulic station filter element

Air compressor inlet filter elementDust collection filter element

Baoan filterPP melt spraying, pleated filter elementHigh flow water filter elementMarine ballast water filter element

Portable oil purifierBox-type oil purifierCoalescing dehydrating oil filterHigh efficiency vacuum oil filter

Customization and designAviation and aerospaceStandard modificationDrawings and samples processing

Standard filter cover modificationFilter elementYPM160AHST130Air cleanerBallast water filter elementLiquid storage tank filter elementCone type filterPure oxygen filterGas station fuel dispenser hose hanger

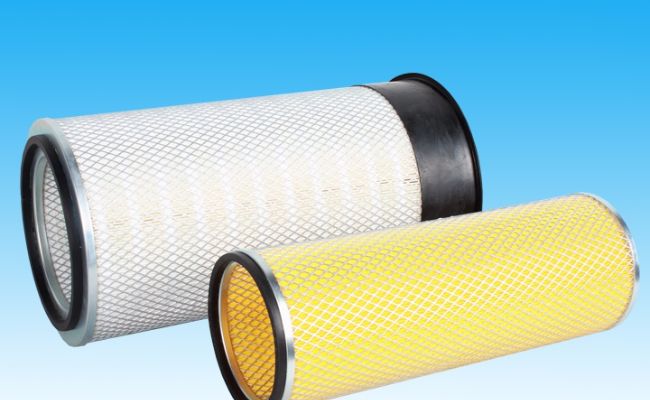

空滤系列产品主要用于发动机及空压机的进气系统过滤,保证气体清洁度。为避免空气中携带的沙粒尘土进入设备,在设备进气口安装空气滤芯。此种空气滤芯多为两级过滤,在外滤芯破损或更换滤芯时,安全滤芯可以起到防止空气中颗粒物通过进气口进入设备的作用。

1.过滤精度为10-15μm

2.过滤效率98%

3.使用寿命可达2000h左右

4.过滤滤材选用美国及韩国进口木浆纸制作

5.1.6Mpa

KLX8025-1/-2(35123512 35123520) KLX157K-1/-2(1433798 1433799) KLX3-1/-2(3222188152 3222188154) KLX4-1/-2(3222188162 3222188164) KLX324K-1/-2(5610969 5610968) KLX1490/-1(2650616390 2650616408) KLX1231-1/-2(15043507 15043506) KLX1590(600-185-6100) | 10微米 | 大于95% | 寿命2000h |

空压机进气系统双级过滤 |

测试标准:

JB/T 10341-2002 滤筒式除尘器

JB/T 9747-2005 内燃机空气滤清试验方法

GB/T450-2008 纸和纸板 试样的采取及试样纵横向、正反面的测定

GB/T453-2002 纸和纸板抗张强度的测定

GB/T 454-2002 纸耐破度的测定

GB/T455-2002 纸和纸板撕裂度的测定

GB/T 457-2008 纸和纸板耐折度的测定

应用领域:

压缩机进气系统

实际案例:

压缩机进气系统